New high-bay warehouse in Bieringen

State-of-the-art warehouse location for ZIEHL-ABEGG’s worldwide unique fan technology

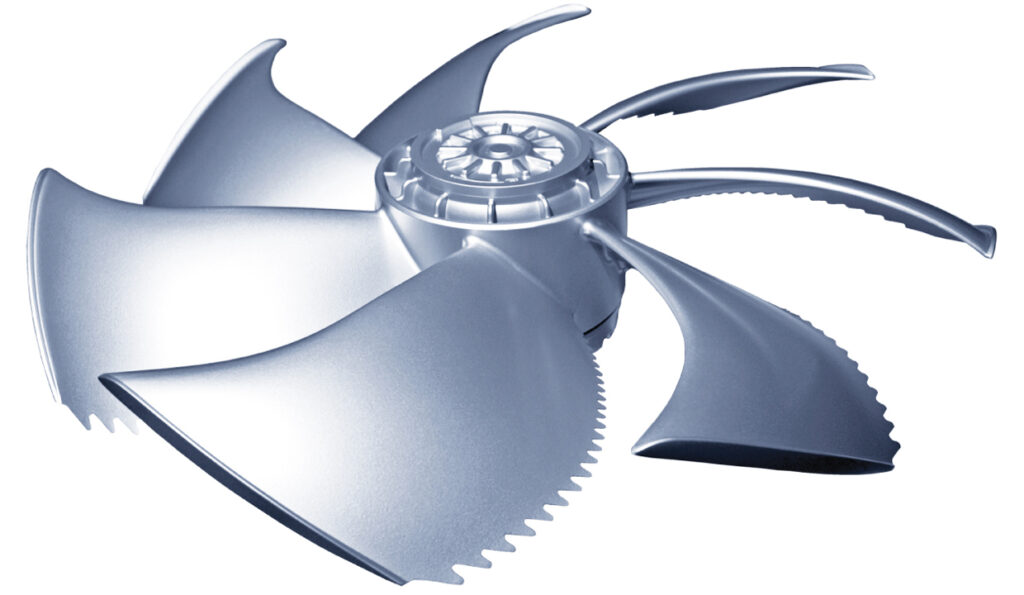

The fan production plant, located between Kochertal and Jagsttal, in the Schöntal district of Bieringen in Baden-Württemberg, has now been expanded with the addition of a modern high-bay warehouse. For more than 50 years, this plant has been developing axial fans and groundbreaking technologies which now set the standard in the global fan industry. ZIEHL-ABEGG produces more than one million motors and fans here every year.

From left to right: Director Bieringen and Hungary Mr. Markus Bruttel, Members of the Executive Board Dr. Klaus Weiß, Dr. Peter Barton, Peter Fenkl (CEO), Team Leader Operational and Building Maintenance Mr. Michael Hock, Member of the Executive Board Olaf Kanig, Head of Materials Management and Member of the Supervisory Board Mr. Hans-Jürgen Pinter

Official opening of the new warehouse building

The new high-bay warehouse at the Bieringen production plant, which had been eagerly awaited by all parties involved, was officially opened in person by the Members of the ZIEHL-ABEGG Board of Directors. From the business viewpoint the ceremony, attended by a small group of people and conducted in compliance with the current pandemic situation, heralds an important improvement in warehousing strategy for the future-orientated production process at the Bieringen plant.

New, modern safety concept for the unique technology

Die-cast rotors (FE2 owlet) up to one metre in size, cast in one single process

ECblue 132 stator bushings

ECblue 116 rotor

AC 137 rotor

With immediate effect, an automated safety and storage concept in the newly constructed high-bay warehouse, designed in accordance with the latest standards and adapted precisely to the local circumstances, will ensure maximum safety and perfect conditions for storage and ordering. This ensures the necessary protection for the products manufactured in the world’s only die-casting foundry which, among other things, produces aluminium rotor castings up to one metre in size in a single process, whilst also securing an extensive range of unfinished parts such as stator bushings and rotors for the extremely wide range of ECblue motors and AC rotors. With storage now automated and robot-assisted, everything in this plant is geared towards the future.