Premiere in London – Fleet Street

Target Lifts Ltd. installs the first ZIEHL-ABEGG ZAtopx elevator drive with StPUGurt (Steel and PU belt)

Right in the heart of London, one of the world‘s great vibrant capitals, the latest, highly-efficient and climate-friendly elevator motor development from ZIEHL-ABEGG, the ZAtopx elevator drive with state-of-the-art StPUGurt concept as means of suspension, is celebrating its‚ „premiere“. Everything about this ultra-modern elevator drive is geared towards the future and meets the requirements for the state-of-the-art transportation of passengers and materials.

ZAtopx is the perfect and flexible solution for replacing old belt drives

The latest elevator drive, which, in combination with the StPUGurt as the means of suspension epitomises innovative and excellent drive technology, proved to be the perfect solution for the renowned Crayford-based elevator company, Target Lifts Ltd., for the purpose of undertaking the pending upgrading work which entailed a number of special requirements.

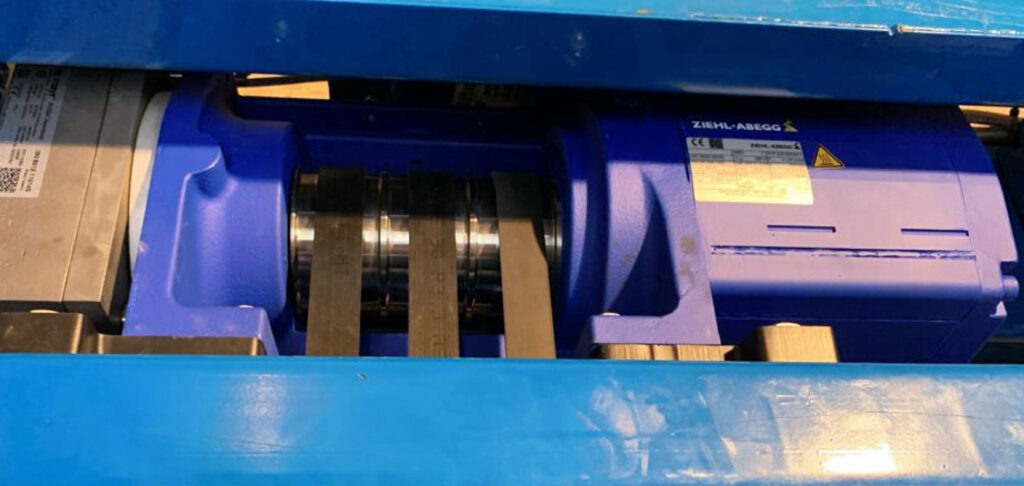

The elevator renovation project is in a 9-storey office building in the heart of the City of London, on the famous „Fleet Street“ main thoroughfare.The aim was to preserve the much-loved elevators which had been in use in this building for many years. However the gearless elevator drives, using rather dated belts as means of suspension and now 18 years old, urgently needed replacement. It wasn‘t an easy matter to find a similar and more future-orientated replacement. With the help of the ZAtopx however, it seemed that this project could be successfully realised.

Superb technical capabilities speak for themselves

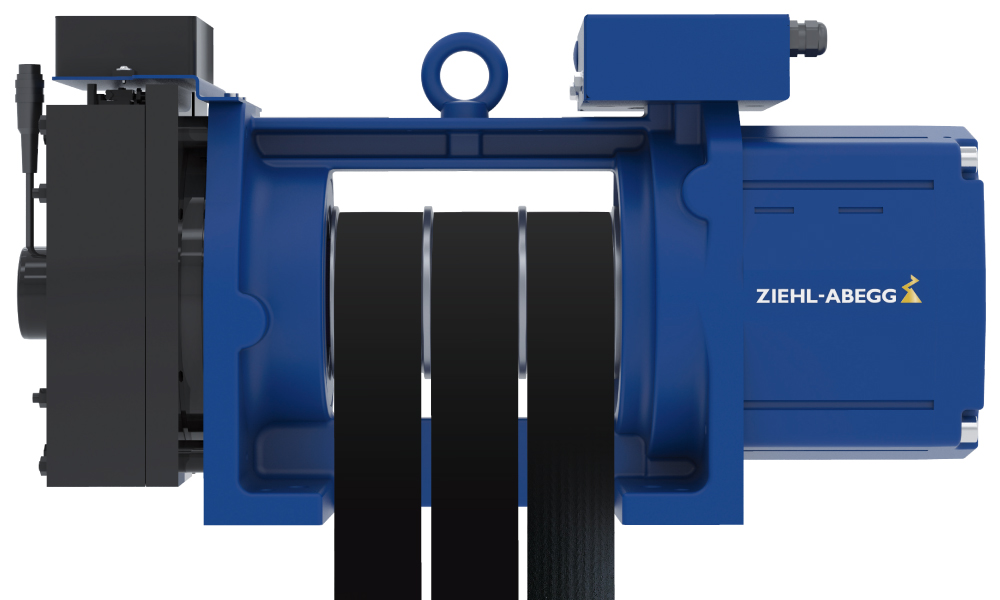

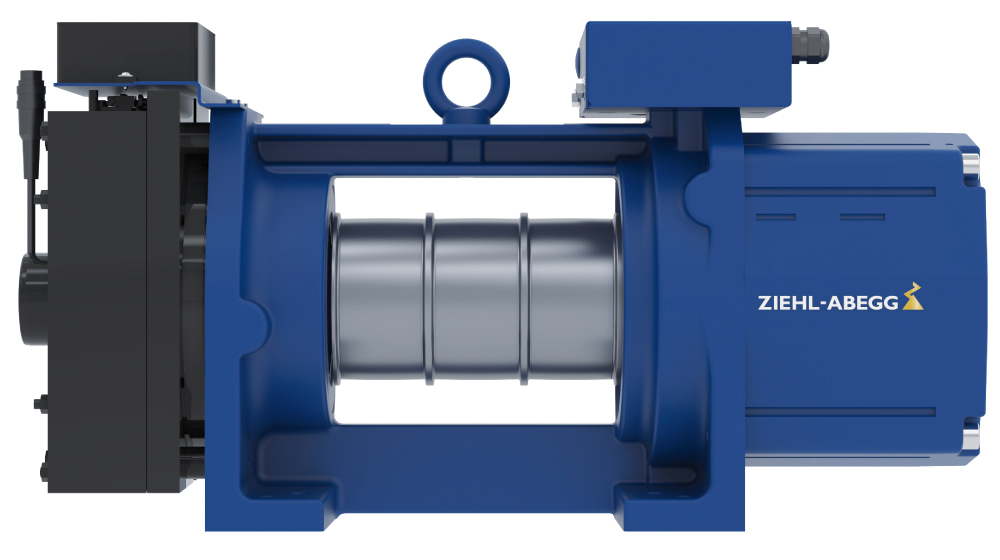

The new ZIEHL-ABEGG elevator drive offered the elevator specialists from Crayford a compatible solution for replacing the old drives. Equipped with high-performance belts made from modern, durable, highly abrasion-resistant and corrosion-free polyurethane material as means of suspension, the ZAtopx, with a 100 mm traction shaft, allowed for installation in the existing, very narrow construction frame.

The excellent design and technical highlights of ZAtopx, along with the excellent associated parts from our manufacturing partners, resulted in a simple and trouble free installation with a successful end result for our customer Target Lifts LTD.

The name of the new way to the top is ZAtopx

Today, the elevators in the London office building are running smoothly with the new ZAtopx drive. Modernised to perfectly meet future requirements and in the tried and tested ZIEHL-ABEGG quality, the drive operates with maximum efficiency, is eco-friendly, very quiet and operates at extremely low running costs.

Successful collaboration

Thanks to the confidence placed it by those in charge at Target Lifts Ltd., ZIEHL-ABEGG was able to provide support for this great project, which was at the same time the premiere-deployment of ZAtopx, in form of a complete one-stop package – technical calculation, drive unit, means of suspension, end terminals for the means of suspension, deflection pulleys and frequency inverter.

Installation data

Payload: 800 kg / Speed: 1.6 m/s

Travel distance: 26 m

Means of suspension: Megalinear 30P3.3 (Megadyne)

3 belts, machine and means of suspension coordinated together.

Drive: ZAtopx BD132.35-3 / Nominal torque: 175 Nm

Traction shaft diameter: 100 mm / Permitted axle load 2,500 kg

Frequency inverter: ZAdyn4CS 017

Deflection pulleys: Supplied by ZIEHL-ABEGG