A giant for high payloads and large traction sheaves

Interlift 2022 – 26 – 29 April in Augsburg with ZIEHL-ABEGG in Hall 1 – Stand 1032

After a three year absence from trade fairs, ZIEHL-ABEGG is showcasing a giant new drive package to its customers. “We have concentrated on the further development of our products in order to satisfy the needs of this sector,” says Thomas Florian, Head of Product Management for the Drive Technology Division at ZIEHL-ABEGG SE.

ZAtopSM315 and ZAdyn4Bplus, giant drive power package – perfectly controlled, quiet and sustainable operation

Giant and sustainable – the future starts today

With the new ZAtopSM 315 drive package and the precision matched ZAdyn4Bplus control technology, the experienced fan motor specialists not only actually meet the needs of customers but have also ‘topped’ the previous system with the addition of the latest technical highlights.

Quiet ‘mega’ power to meet the most stringent requirements and heavy loads

Powerful, highly-efficient package for carrying payloads up to 5,000 kg

Quiet, fast and reliable travel in the event of an emergency

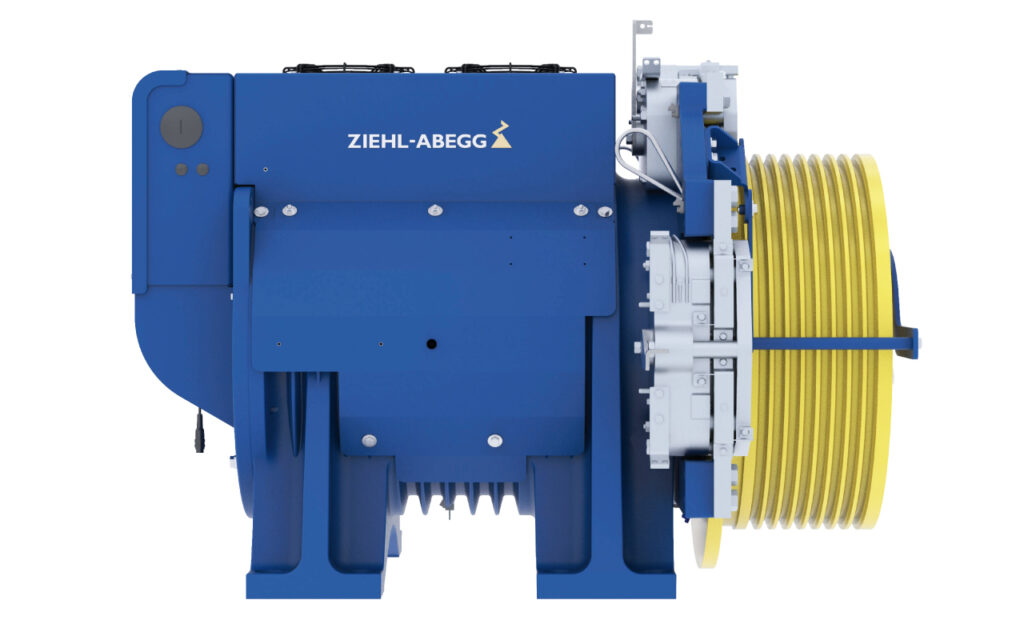

The gearless ZAtopSM315 effortlessly handles the heaviest payloads of up to 5,000 kg through the use of traction sheaves.According to the developers at ZIEHL-ABEGG, the maximum axle load and the required torque were crucial in the design of the machine during the product development. The fully enclosed traction sheaves also provide more enhanced protection and consequently more comprehensive safety.

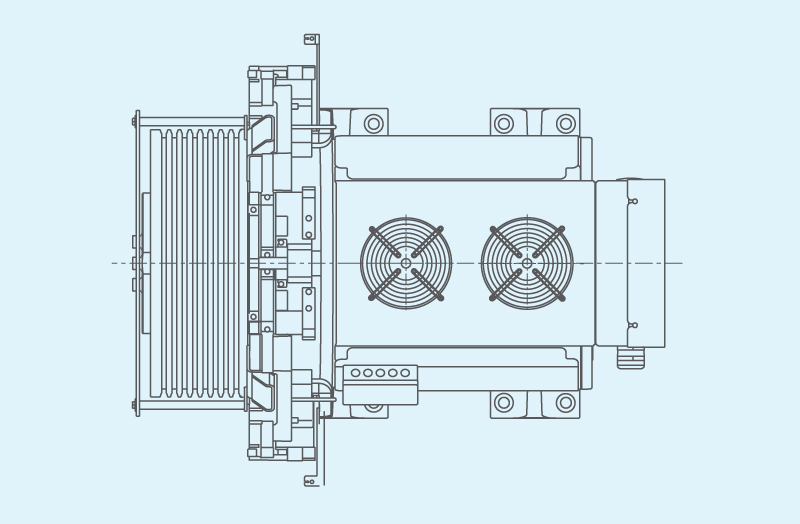

Compact dimensions of the clever drive design

The compact dimensions of the clever drive design play an important role in making transportation and installation as easy as possible. With newly designed removable brakes, the technicians have reduced the machine width of the ZAtopSM315 to less than 900 mm. This means that opening and closing the doors will also no longer pose an insurmountable obstacle in the future.

Without motor protection and with electric short-circuit for the motor winding

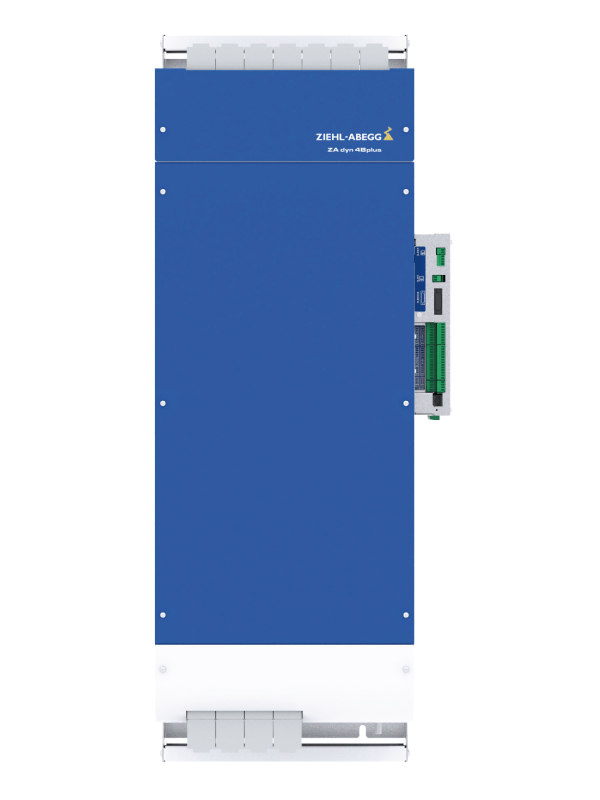

ZAdyn4Bplus – state-of-the-art control technology without motor protection

An additional extra and further highlight is the ZAdyn4Bplus control technology specially adapted to suit the upper power range. What makes the new, high-performance control technology for motor currents up to 220 A impressive – unique in this performance class – is the fact that the package operates without motor protection and with electronic short circuit of the motor winding. With its integrated energy-saving programme, the ZAdyn4Bplus also reduces energy costs and, together with the ZAtopSM315 premium quality drive, makes a significant contribution towards sustainability and climate protection for future generations.